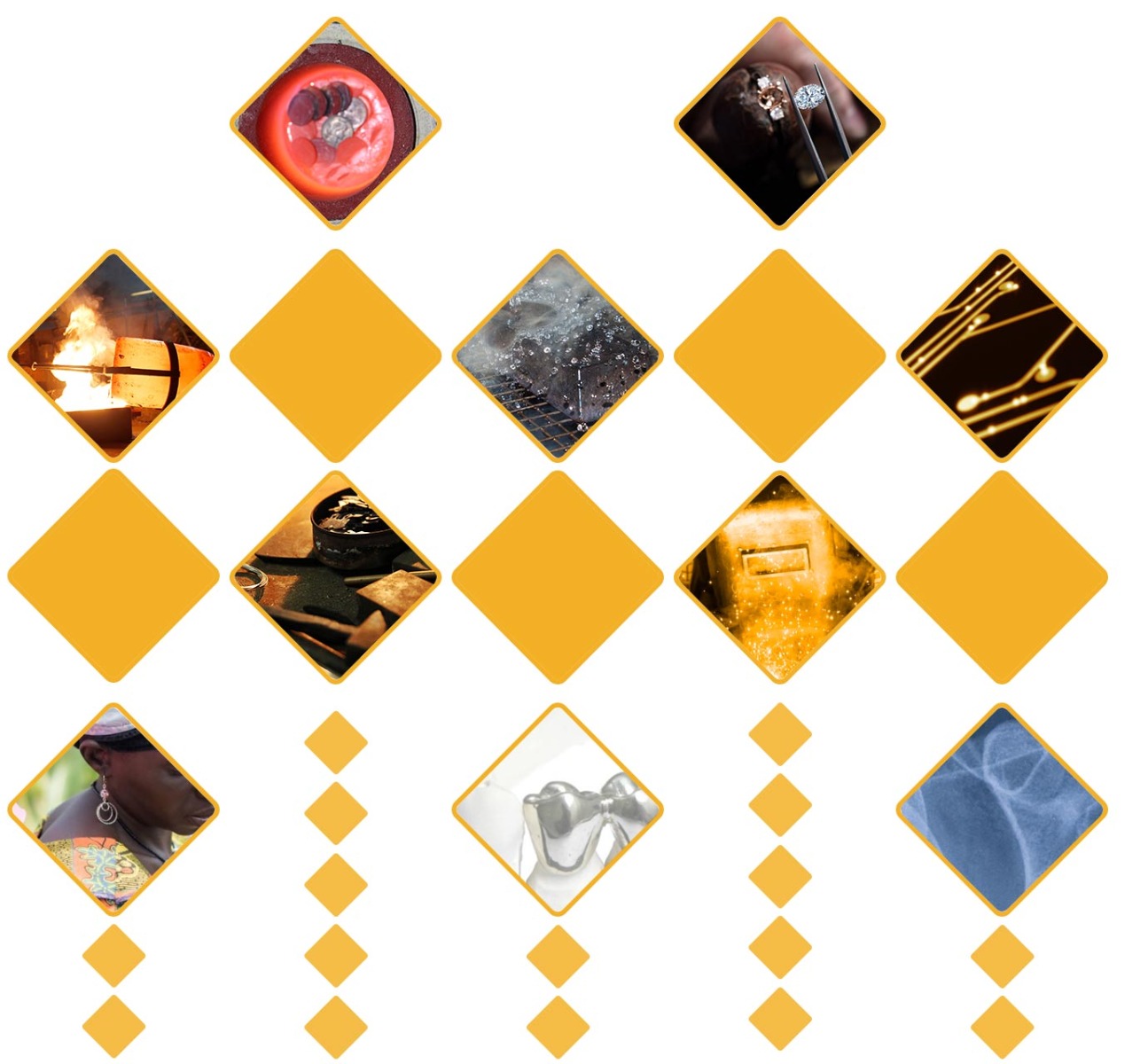

Smelting and Refining of precious metals

Now into its fourth century of trading, the ninth consecutive generation of Betts family management is proud of the company’s long history of integrity and commercial strength. Throughout this time, our core principles have been to provide ‘quality’ and ‘service’ – two words that are easily used but rarely fulfilled. These two qualities are the founding principles of all the Betts Group businesses today.

Stephen Betts & Sons Ltd is the refining arm of the Betts Group and combines the wealth of experience generated from nearly a quarter of a millennium of operation, with modern, technically advanced processes, to provide a complete service in the smelting and refining of precious metals. The company’s factories contain the latest in recovery equipment, which makes possible the smelting and refining of lower grade wastes containing precious metals such as gold, silver, platinum and palladium. Precious metals can be recovered from many different sources and processes. We recover precious metals from all types of waste; particularly those generated by the jewellery, ceramic, photographic, industrial and dental professions, although our experience also covers many other industries. Whatever the source, our highly trained staff process the materials to ensure the highest possible recovery of precious metals. All recovered materials are sampled and assayed independently to ensure a transparent process, and the customer is informed of the value in line with London market prices.

Stephen Betts & Sons is one of the only ‘true’ refineries in the UK, with the ability to refine back to 9999 purity in house. Our wealth of knowledge in extractive techniques also enables us to offer diamond and gemstone recovery from scrap; a technique which very few companies in the UK are able to offer. We are proud that our refinery in Buxton is the only Fairtrade and Fair Mined certified refinery in the UK and our experience in auditing small batch segregated refining also makes us the only UK refinery offering Single Mine Origin gold.

Once we have recovered precious metals through our refining operations, we provide a comprehensive range of bullion and investment products back to the market through Betts Metal Sales and Betts Investments.

Clean Scrap

We deal with all forms of precious metal waste from the jewellery industry, from clean hallmarked scrap and lemels, right through to large, low grade sweeps and hand-wash tanks. We even go as far as recovering the metal from old carpets and floorboards in old workshops.

The Betts Group offers competitive rates on all alloys of clean scrap. Through use of XRF technology, we are also able to offer immediate payment clean scrap.

We aim to be highly flexible in making your scrap work for you. We are therefore able to offer immediate returns by cash, cheque or bank transfer. Alternatively, it is possible to credit clean scrap to a metal account and make use of our extensive manufacturing capabilities to draw back your precious metal in product form.

Stone Recovery

The Betts Group specialist chemical recovery process allows customers to maximise their returns from scrap by enabling diamonds and gemstones to be recovered and returned undamaged.

Unlike smelting and other chemical recovery processes, our process ensures that all precious metals are recovered whilst avoiding damage to precious diamonds and gemstones. We are the UK’s leading experts in recovering diamonds and precious gems from jewellery scrap.

Sweeps & Lemels

With roots back in 1760, Stephen Betts & Sons is one of the oldest and best trusted names in the refining world.

The original business was founded in Birmingham’s jewellery quarter in order to service the newly flourishing jewellery trade and we have been extracting precious metals from sweeps and lemels for over 250 years.

Although modern technology has enabled us to maximise customer returns, generating great returns for our jewellery customers from sweeps and lemels and consequently building long term relationships with those customers has been at the heart of our success for over quarter of a millennium.

Because all of our processing of sweeps and lemels takes place in-house, right through to returning gold to 9999 purity, we are able to offer both the best and the quickest returns in the industry. We are also highly flexible on payment terms, with many of our customers choosing to have their metal recycled into one of our many in-house manufactured products.

Workshop

We specialise in recovering precious metals from extractors, filters, hand wash tanks (which we can also install), sweepings, rags, carpets and even old workbenches. All these materials are processed in house to generate the maximum possible returns for our customers. We are also able to provide a full range of jewellers’ tools through our tools division in Betts Metal Sales should you require assistance with refurbishing your workshop alongside advice regarding best workshop practice to maximise precious metal returns.

Solutions

The Betts Group has both the in-house chemical expertise and the correct environmental licences to treat all such solutions effectively and in-house. We process a very broad range of solutions, achieving maximised recovery of precious metal contents for our customers.

Ceramics & Transfers

The Betts Group establishes long-term relationships with customers in the ceramics trade, who are significant users of precious metals and for whom we generate lucrative returns by recovering precious metals from broken pottery, transfers, solutions and rags. All these materials are processed swiftly and efficiently at our sites in Buxton and Kidderminster.

Plated Materials

The Betts Group specialises in stripping precious plating from other materials and recovering these precious metals back from solution. Although modern plating methods allow for incredibly thin layers of precious metals to be utilised, the returns to our customers can still be very significant.

Bronzing Alloys

Brazing alloys can be complex, requiring significant expertise to efficiently refine and recover the precious metal elements. Stephen Betts & Sons has this expertise and can process all brazing alloys in-house, providing customers with excellent returns on their brazing alloy wastes.

Ethical Refining

We believe the chain of custody is becoming increasingly important to consumers across all sectors. We also believe that gold mining, whilst having a chequered reputation, can be a force for good in developing countries as long as it is conducted responsibly, ensuring that local communities share in the economic benefits a mine provides.

Our in-house manufacturing capabilities allow us to offer a broad range of Fair Trade, Fair Mined, Single Mine Origin and recycled bullion products, including grain, sheet, wire, wedding rings and investment products. Stephen Betts & Sons can also provide reprocessing services for Fair Trade products.

Doré bars

Stephen Betts & Sons offer swift and highly efficient refining of doré bars through our refinery in Buxton. We are able to process doré bars to 9999 purity in a very short timeframe irrespective of volume.

We specialise in small batch, segregated refining of doré bars and are currently the only UK refinery to refine Fair Trade and Fair Mined gold; a process which is fully audited by an external auditor. Our highly flexible team are able to refine doré bars quickly and cost effectively, even if batch loads are relatively small.

Dental

Although less precious metal is utilised in the dental industry at present, with government cost savings forcing dental technicians into utilising inferior non-precious alloys for crown and bridge restorations, some precious metals do remain utilised and Stephen Betts & Sons can efficiently recycle all precious metal bearing dental wastes including waste alloys, platinum foils and dental sweeps.

As with all our refining work, these waste streams are processed quickly and efficiently in house, giving our dental customers the best possible returns for their waste.

Film

Through our environmental division, Betts Envirometal, Stephen Betts & Sons is the leading UK recycler of X-Ray film.

We have extensive contracts with a range of blue-chip companies and many NHS trusts who rely on us to securely destroy their X-Ray films, recycle the materials involved and provide excellent returns by efficiently recovering the silver content from this film.

Our in-house chemical silver recovery process is environmentally friendly, ensuring that whilst all records are fully destroyed, we are also able to recover all silver content and recycle the PET and paper elements. X-Ray film archives, especially from industrial sources where it has been used for non-destructive testing, can have surprisingly high silver content and generate large returns for our customers.